Digging or boring anything comes with some inherent risks.

If you need to bore into concrete, you face some special challenges. A major risk in concrete boring is hitting something you didn’t know existed! Concrete scanning before excavation or removal can reveal hidden dangers, saving time and money.

Concrete can hide a lot of things – rebar, wiring, pipes, vaults and a host of other buried objects. These objects can be a ticking time bomb. Hitting an unmarked object can damage your boring or cutting equipment. It can also take out live utility connections that will be expensive to repair or replace. In either case, you’ll spend time and money repairing the inadvertent damage.

What is Concrete Scanning?

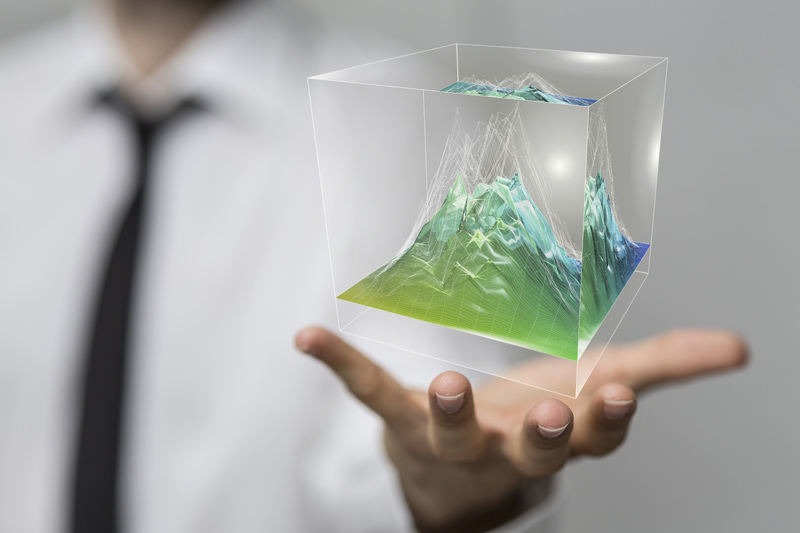

Concrete scanning can reveal the presence and exact location of objects hidden underneath or within existing concrete. 2-dimensional and 3-dimensional ground-penetrating radar scans are non-destructive because they’re created using sound waves. The scan will render a complete picture of what lies in and around the target work area.

White Shield offers concrete scanning services.

We can provide comprehensive scanning data early in the planning stages of a project. You’ll know immediately what you’ll encounter during drilling, boring or cutting. By knowing what lies beneath the surface and its precise location, you can adjust your plan accordingly, saving time and money in the process.

Scanning isn’t just for horizontal surfaces. It is a must for construction or renovation planning in concrete buildings. High-quality concrete scans will identify and locate communications and electrical conduits, rebar, support beams, tension cables and other objects obscured in formed concrete.

Using scanning equipment, we can mark critical locations directly on concrete surfaces to identify hazards. Identification of hazards helps to keep employees safe and reduces the risk of downtime or unintentional structural damage.

In addition to identifying hazards in and around concrete work, scanning can also assess the concrete. Scan data can pinpoint the thickness of a slab, the presence and composition of rebar or other reinforcing materials, and its precise location inside the concrete. Knowing where rebar, conduit, and other components are and how the spacing can help personnel to plan renovations effectively.

Benefits of ground penetrating radar and concrete scanning

As important as knowing where objects are, it’s equally important to know where they aren’t! Ground penetrating radar and concrete scanning can also detect voids in and around concrete and asphalt. Voids sometimes form because water or other liquid intrusions wash away sub-surface support materials. Voids are commonly found near underground pipes, like sewers and drains. Concrete scanning can detect and assess potential void hazards before a catastrophic collapse occurs.